Yuan Zhao

About Me

Now I’m a postgraduate in RAIL, Robotics and Artificial Intelligence Lab which started in 1990 and is one of the earliest laboratories in China engaged in the research of robotics and artificial intelligence.

My main research field includes high-performance control platform of industrial robots and collaborative robots, such as robot control platforms, robot teaching software development and trajectory planning algorithms.

Click here to see my resume.

Robot Demonstrator Robot Controller Trajectory Planning

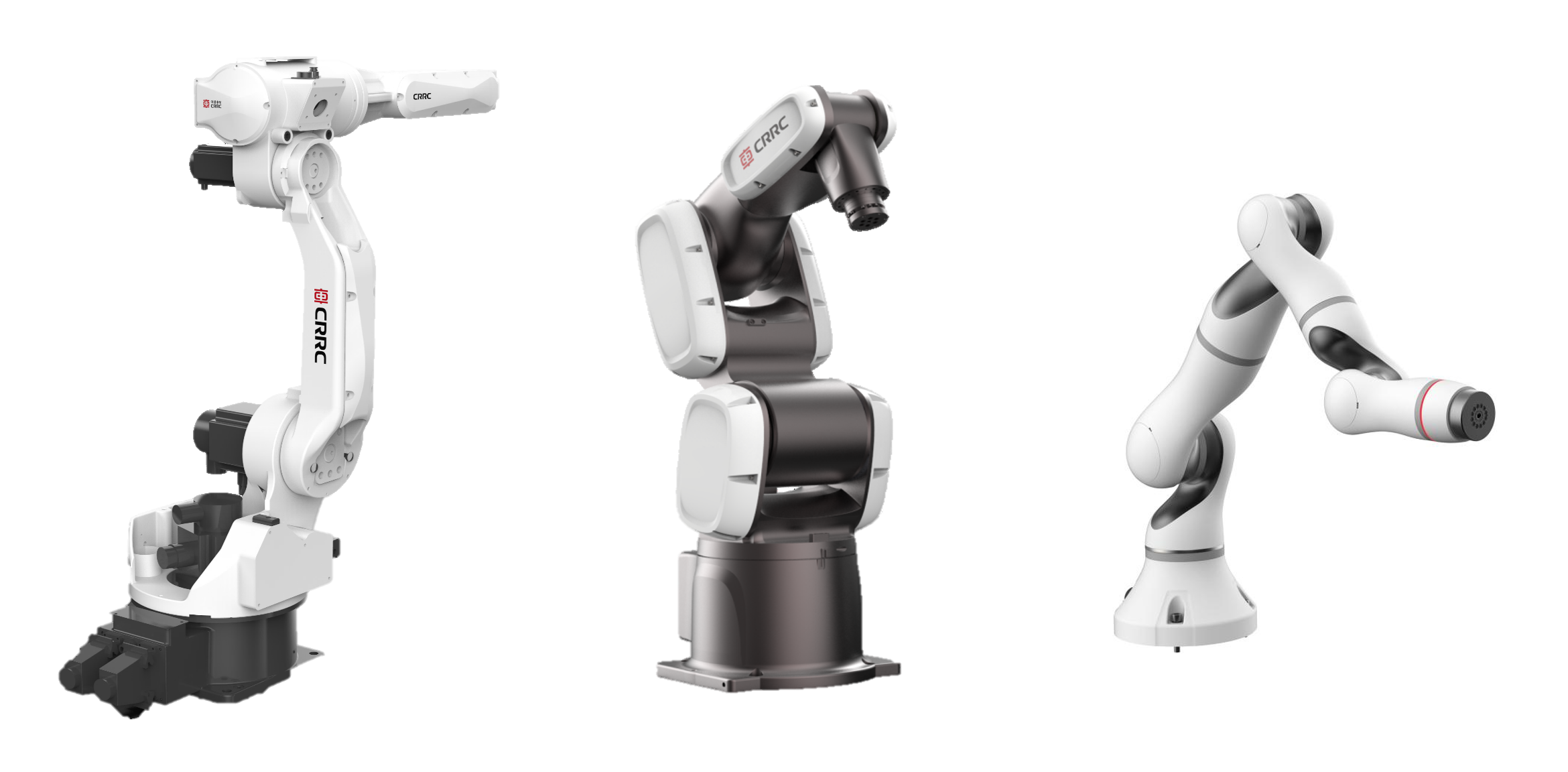

Robot arms our team developed with CRRC Sifang Co., Ltd.. First two are six-axis industrial robot and the last one is a seven-axis collaborative robot.

Robot Controller

- General control system based on an overall architecture of IPC RTOS with fieldbus.

- Three-layer software architecture: Communication and Task Analysis Layer, Task Execution Layer and Data Interaction Layer.

- Compatible for six/seven axis robot, DELTA robot and SCARA robot.

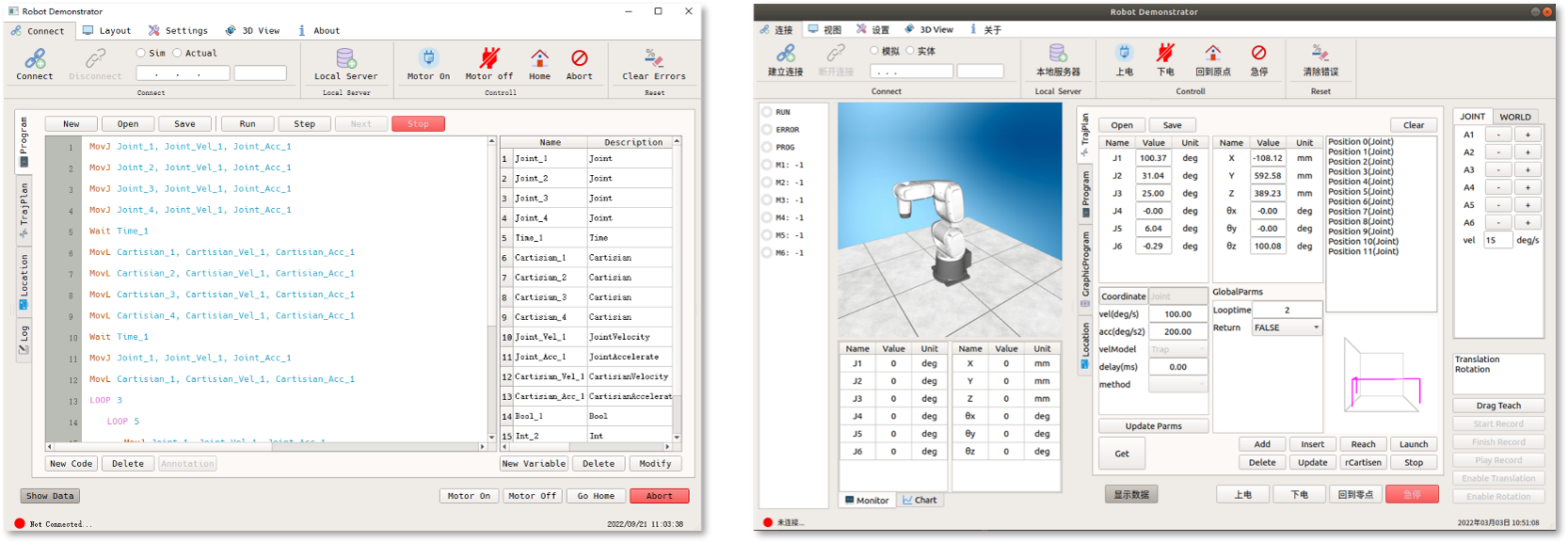

Robot Demonstrator

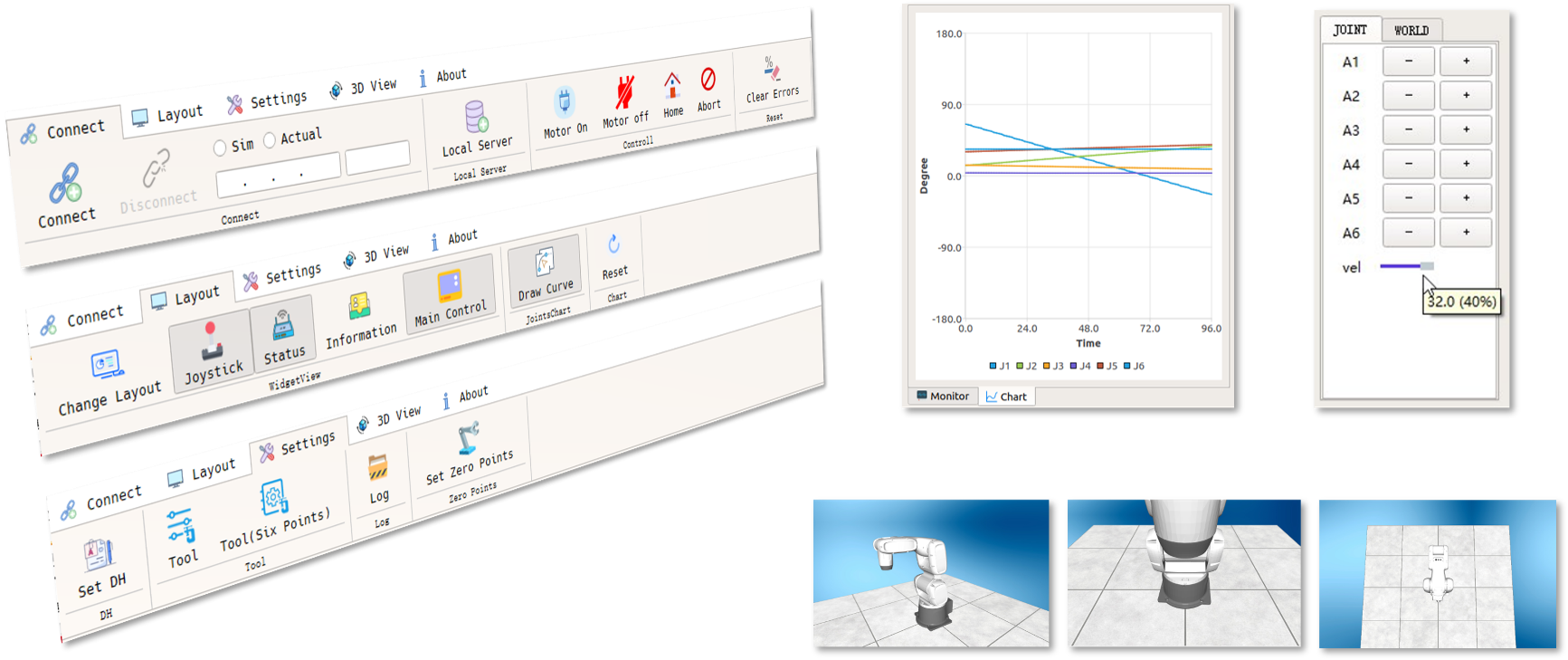

For industrial robots, in addition to the mechanical body, control system, and servos, a very important component is the teaching system. Through the teaching system, the operator can view the operation information of the robot and control the robot to move to the designated position by sending operation instructions.

- 3D simulation display, mouse interaction, camera switching. The more real the 3D visualization module is, the more it can show the robot model and the running status of the virtual robot to the user. Now support specified six and seven axis robot STL files, other kinds of robot can be easily adapted.

- Cross-platform, now it can run under Windows and Ubuntu of x86 architecture, and ARM version of Linux is also supported. Compatible for six/seven axis robot, DELTA robot and SCARA robot.

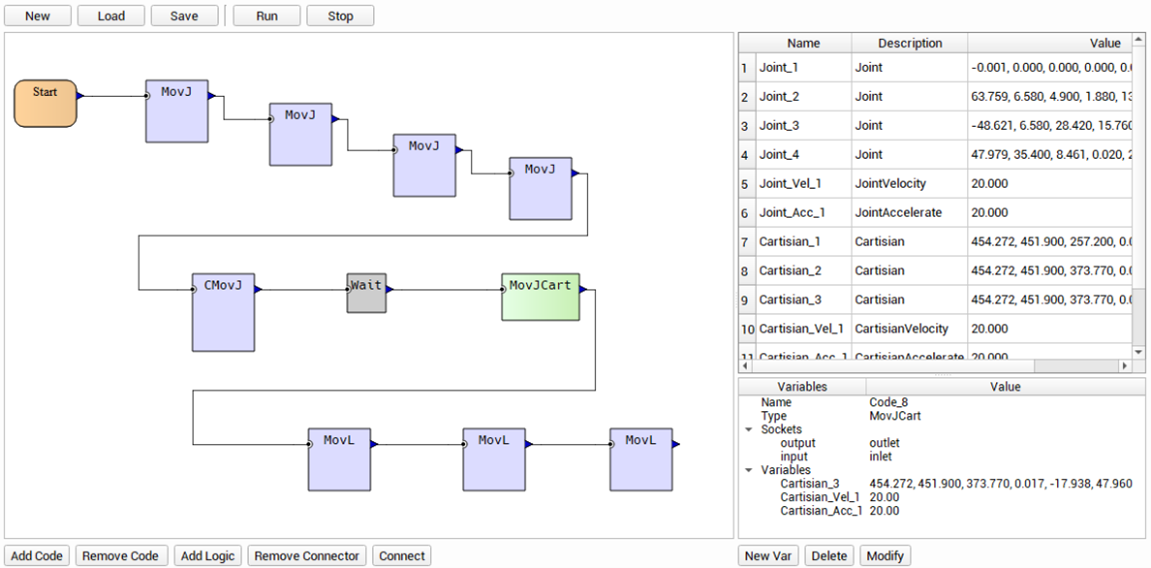

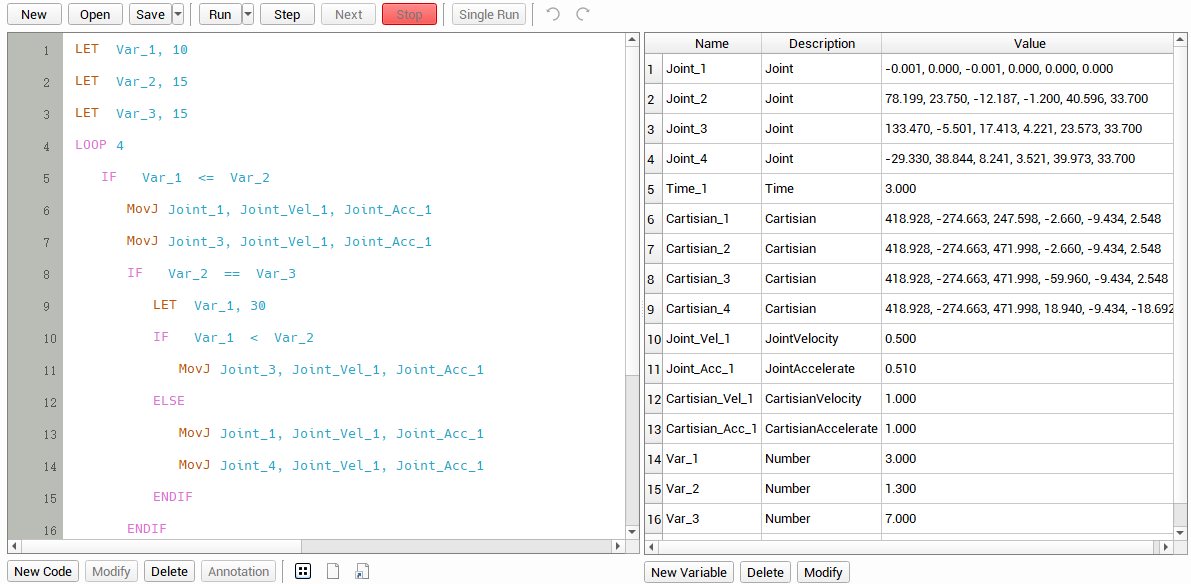

- Support text-based robot programming with motion control instructions such as MovJ, MovL etc. Conditional selection instruction like IF/ELSE/ENDIF and LOOP etc. also supported. Graphic-based programming under development.

- Modern HDI, simple and easy to use.

Trajectory Planning Algorithm

-

Trapezoidal velocity model or cosine velocity model for joint space trajectory planning and Cartesian space trajectory planning.

-

Multiple points planning with quintic polynomial method for joint space planning.

- An algrithm named GGP with combination of quintic polynomial method and GA-PSO for smooth and time-optimal joint space planning.

Where $f_{time}$ stands for the total time of the whole trajectory, $f_{\eta}$ stands for the energy cost in the whole trajectory, $f_{acc}$ and $ f_{vel}$ are the velocity and acceleration boundaries.

Obstacle Avoidance

When obstacles are taken into consideration, in order to make the robot complete some specified tasks safely, it is extremely necessary to achieve an obstacle-avoidance trajectory planning. Such algrothism can further expand the planning capabilities of the robot control system.

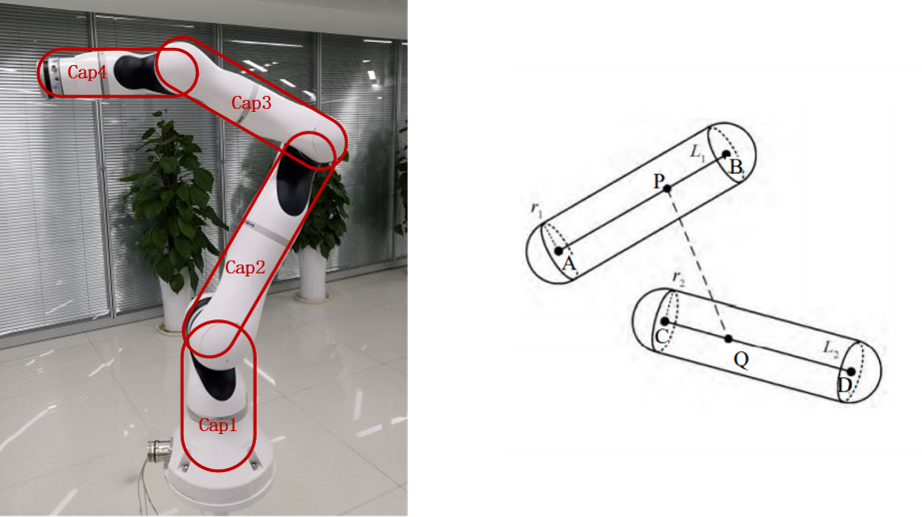

- Capsule-collider method for self-collision detection.

- AABB (Axis Aligned Bounding Box) and Slabs Method for external-collision detection.

- Sixth degree polynomial method and GA-PSO for joint space obstacle-avoidance trajectory planning.

The picture above shows the trajectory planning without considering obstacle (left) and the trajectory planning considering obstacle (right).

Acknowledgements

Sincerely thanks to my tutor Prof. Chen and my friends and teammates Xianyou Zhong, Haoran Sun, Liang Tang, Zhengang Huang, Heng Zhang, Xianghui Pan and Zhengkai Ao.